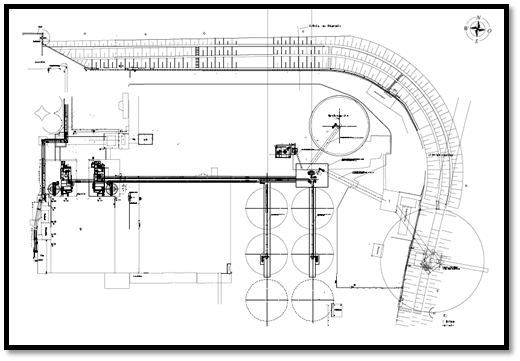

Revamping Project - Port Installation - Argentina 2019

This project involved a feasibility analysis and front-end engineering to revamp and upgrade an outdated storage and river port facility, covering all engineering disciplines.

Piping Project Design and Execution - Supervision - Argentina 2018

The project consisted of detailed engineering and site supervision for the piping installation of soybean lecithin, water, steam, fuel oil, and compressed air in a leading industry plant. This comprehensive endeavor ensured the integration of various systems into the newly constructed plant.

Rice Chillers Design - Qatar 2019

In this project, we conducted simulations to assess the performance of grain cooling systems in silos exposed to Qatar's extreme desert climate. Our analysis evaluated heat transfer effects, identified the most heat-affected silo, and optimized cooling strategies to maintain rice temperatures low. The study compared different construction materials, including steel and concrete roofs, to ensure efficient and reliable rice preservation.

Port and Mechanical Handling Expert - Qatar 2019

In this project, we provided technical specifications, detailed design drawings, and logistics analysis for port equipment and material handling systems, including conveyors, ship unloaders, self-propelled hoppers, and rice processing equipment. Our scope covered equipment integration, procurement support, capacity analysis, and port operations planning to optimize material flow from shore to storage and processing facilities. Additionally, we assisted in civil and infrastructure design to ensure optimal operation and efficiency.

Port expansion project - Paraguay 2020

Lorem ipsum, dolor sit amet consectetur adipisicing elit. Sint magnam sapiente totam minus suscipit maiores, libero deserunt sequi rerum voluptatibus vero.

Pipeline Project execution - Madagascar 2022

We provided engineering design, pipeline routing assessment, hydraulic calculations, and procurement support for a 10 km long vegetable oil pipeline connecting the port to a refinery. Our scope included pipeline installation specifications, equipment layout, material selection, and P&ID development, ensuring optimal flow, pressure management, and operational efficiency. Additionally, we conducted budget analysis, coordinated procurement packages, and project management to align construction with cost, quality, and schedule requirements.

Plant Energy Efficiency Improvement Project - Argentina 2022 - 2023

We conducted detailed energy audits across multiple facilities of two companies, focusing on compressed air systems, transport systems, fans, pumps, chillers and other high-energy consumption equipment, to identify optimization opportunities. Our scope included equipment performance analysis, efficiency benchmarking, and identifying high-impact improvements while ensuring alignment with existing engineering data and manufacturer specifications. The results provided actionable insights for reducing energy consumption and improving operational efficiency in key industrial processes.

Seed Processing Plant Storages Design - Germany 2023

In this project, we provided technical specifications, design drawings, and logistics analysis for silo storage and material handling systems, including silos, conveyors, bag filters, and ancillary equipment. Our scope covered equipment integration, procurement support, capacity analysis, and consultations with suppliers to optimize material flow to storage and processing facilities. Additionally, we assisted in general design to ensure optimal operation and efficiency.

Steam Turbine Generation Set - Argentina 2024

We provided project management services from the feasibility stage through to commissioning, ensuring compliance with client's requirements and Argentine regulations. Our scope included feasibility analysis, engineering specifications, bid package preparation, and overall project coordination across process, civil, mechanical and electrical disciplines. Additionally, we managed construction planning and site supervision to ensure successful execution and integration of the steam turbine system.